Pitcox

Battery Energy Storage System

East Lothian, Scotland

Get to know the project

Pitcox

Battery Energy Storage System (BESS)

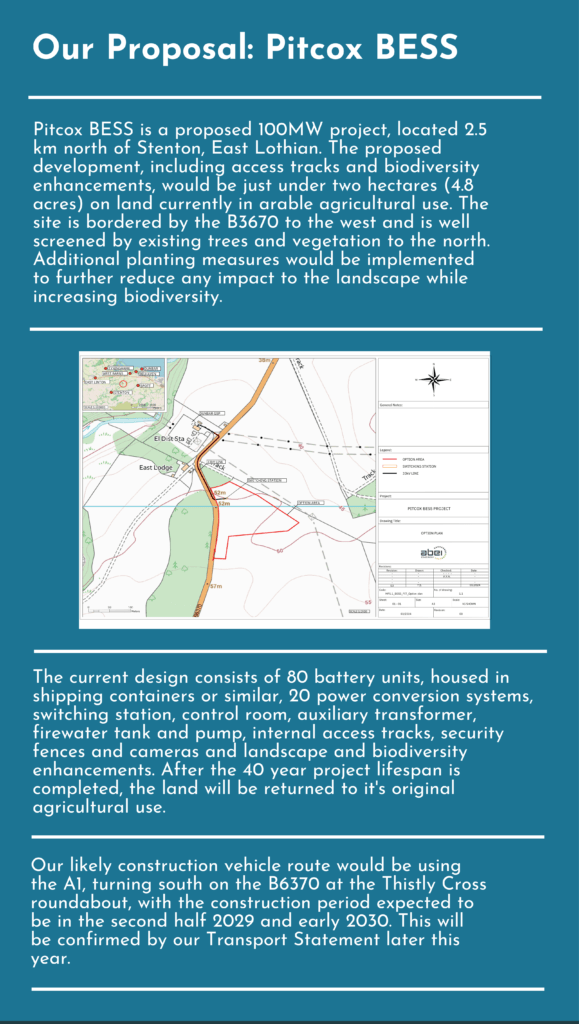

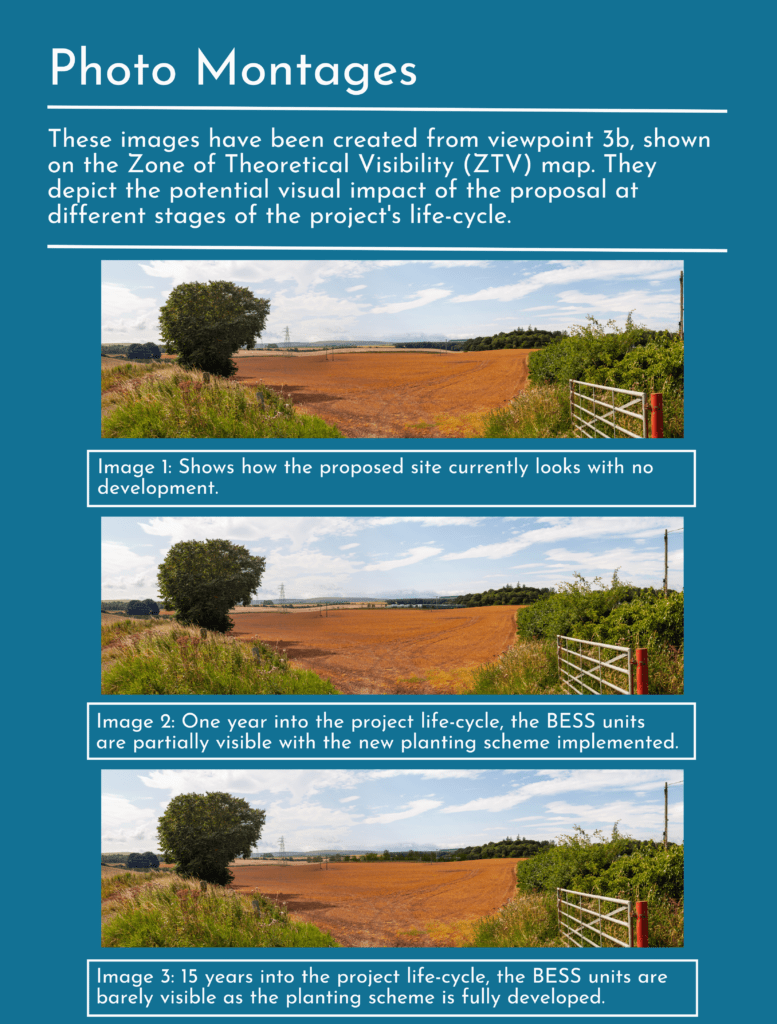

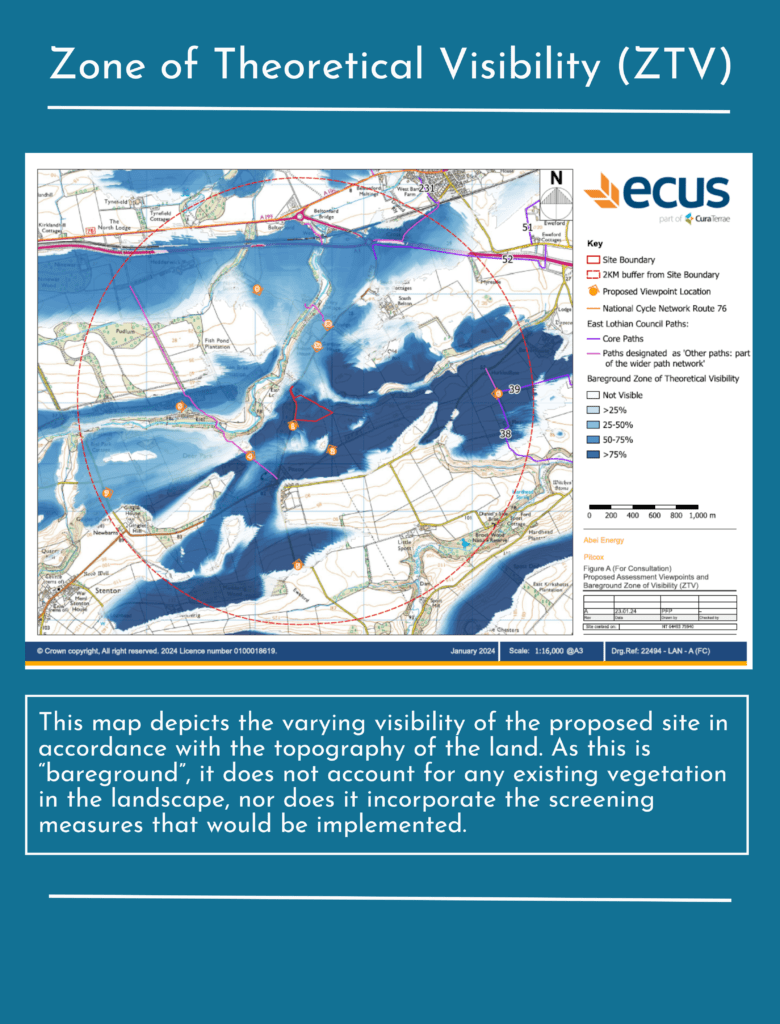

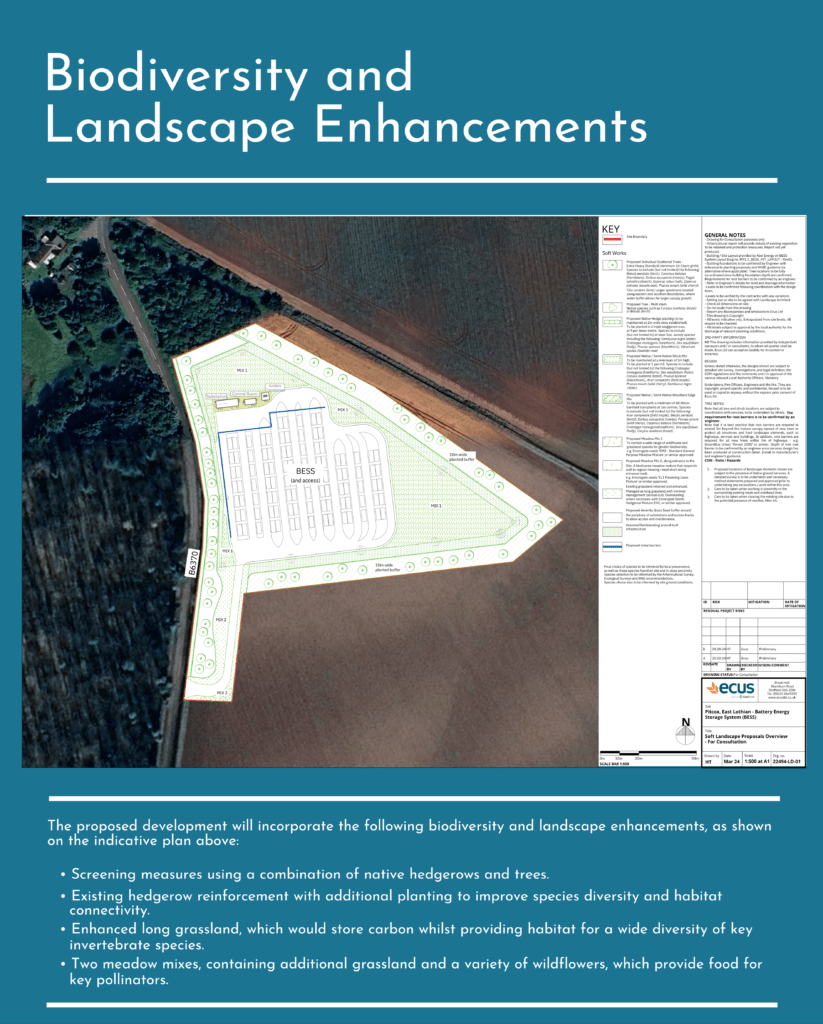

Pitcox Battery Energy Storage System (BESS) is a proposed 100MW project, located 2.5 km north of Stenton, East Lothian. The proposed development would be located on approximately four acres of land currently in arable agricultural use. The site is bordered by the B3670 to the west and is well screened by existing trees and vegetation to the north. Additional planting measures would be implemented to further reduce any impact to the landscape while increasing biodiversity.

Project phases

Type of installation

BESS

Location

Stenton, East Lothian

Scotland

Stoarge Capacity

100MW

Across 4 acres

Curtailment Reduction

Supporting Renewable Energy Generation

Through Energy Storage

Homes Powered

~ 150,000

During Peak Hours

Biodiversity Net Gain

+ 84% BNG

Through arable reversion and habitat creation

Decomissioning

40 Year Lease

95% of materials recycled

Community Benefit

£400,000

Across the lifetime of the project

About Us

We drive change

We are a team of passionate people who bring good energy to the world and drive positive changes for a more sustainable future. Our team accelerates the energy transition in 8 countries within Europe and America.

What makes us different?

We care about the quality of each process. That is why we manage the entire life cycle of energy projects, from their origin to their operation and maintenance, and the management of the resulting assets.

Public Consultations

We have held two Public Drop - in Events for Pitcox

Planning Application Submisson

November 2024

Planning Application Determination

We are currently awaiting on a decision from the Energy Consents Unit.

FAQs

What is a BESS and why is it needed?

A Battery Energy Storage System (BESS) stores energy generated from renewable sources like wind and solar. It allows electricity to be stored when there is an oversupply (e.g. on sunny or windy days) and then discharged when demand is high. BESS improves grid reliability by helping to balance supply and demand, support grid stability during frequency disruptions, and reduce the risk of blackouts. As coal and gas generation are phased out, BESS plays a crucial role in supporting a low-carbon, renewable-powered energy system.

What is involved in designing a BESS?

Designing a BESS involves a wide range of considerations, including:

Proximity and connectivity to the grid

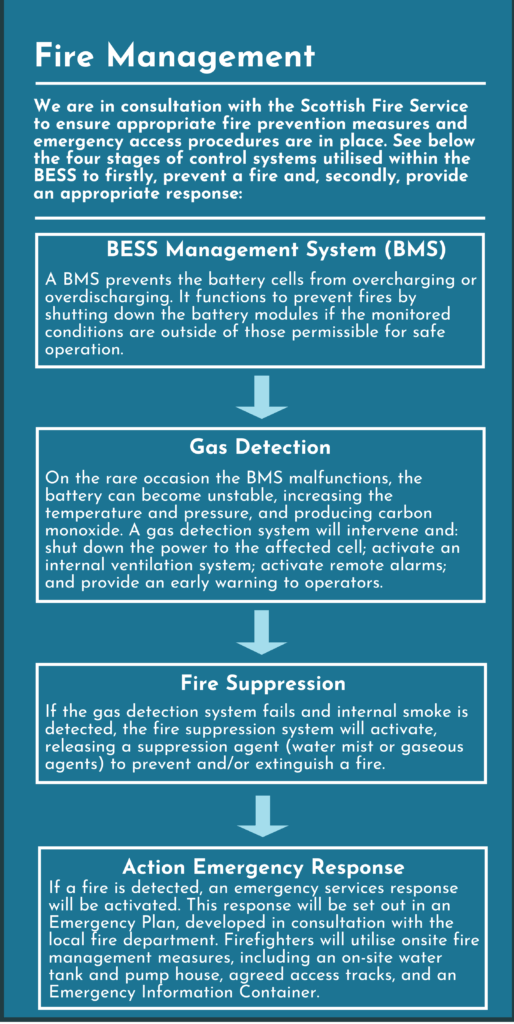

Fire safety and overall safety standards

Compliance with relevant standards, guidelines, and legislation

Practicality of construction (constructability)

Potential environmental, residential, and heritage impacts

Operations and maintenance requirements

Project costs

What environmental studies are carried out?

Environmental constraints are identified early in the design process to help minimise impact. Detailed assessments are undertaken by specialists and typically include:

Biodiversity

Cultural heritage

Noise

Traffic

Landscape and visual impacts

Hydrology and flood risk

These studies support the planning approvals process and ensure that potential impacts are properly mitigated.

Where is the lithium for the batteries sourced and built?

Lithium is mined globally, including in South America, Africa, and Australia. The UK signed a Free Trade Agreement with Australia in December 2021, and Australia is currently a key lithium supplier. Although importing lithium has environmental costs, lithium can be infinitely recycled without losing performance. In June 2023, it was also announced that lithium mining would begin in Cornwall, which could eventually meet around two-thirds of UK battery demand. Currently, most batteries are imported. However, the UK Government has committed to developing domestic battery production using UK-mined lithium. Once operational, these battery factories will significantly reduce the carbon footprint associated with battery manufacturing and transport. In the short term, some imports will still be necessary to meet demand, but UK-based production is expected to improve sustainability in the long run.

What can be recycled from a BESS?

Decommissioning of BESS facilities follows strict regulations to ensure safe disposal and recycling. The industry is working towards circular economy goals. Components that can typically be recycled include:

Concrete bases: Crushed and reused in other construction projects

Fencing: Removed for reuse or metal recycled

Electrical equipment: Reused or dismantled for parts

Batteries: Metals like lithium, copper, and nickel are valuable and recyclable

Some plastic materials are currently harder to recycle, but the recycling industry is advancing rapidly. Companies like Veolia are developing more efficient methods to recycle battery components.

What should I expect during construction?

Most vehicle movements will occur during the construction phase. A Traffic Management Plan (TMP), available under documents.

We Want To Hear From You

Contact Us

Do you want to know more about the Pitcox site?

We would love to hear from you. Fill out the form and we will get back to you as soon as possible. Whether it is a question about our process, a suggestion or you simply want more information, we are here to help.

Our team is ready to provide you with the best service and answer all your questions. Do not hesitate to write to us, together we promote a more sustainable future!

Address Abei Energy

Regus, 83 Princes St, Edinburgh, EH2 2ER

developmentuk@abeienergy.com